How Green Is My Hydrogen?

Green hydrogen subsidies in the IRA act could spark a whole new industry in the US. But they could also result in a significant increase in emissions from hydrogen production. Find out why?

May 7, 2023

The recently passed and confusingly misnamed “Inflation Reduction Act” in the USA includes massive tax credits for the production of “green” hydrogen. Hydrogen is a colorless gas, but the bureaucrats that have taken charge of our efforts to combat climate change have painted it with colors that depend on the method by which it is made.

Thanks for reading Jaberwock's musings! Subscribe for free to receive new posts and support my work.

Green hydrogen is hydrogen produced from water, by electrolysis, using electricity that has been produced from “green” sources. Those sources include renewable energy such as wind, solar and hydroelectric power. But hydrogen produced from nuclear power, despite being just as green, gets its own color designation, it is called pink hydrogen.

Most hydrogen in the world today is made by steam methane reforming. Natural gas (methane) and steam are reacted at high temperatures in a two-stage process that produces CO2 as a waste product. The CO2 emissions from steam methane reforming of hydrogen, including the chemical reaction and the energy needed to operate the plant are estimated to be 9,300 g CO2 per Kg of hydrogen.

Hydrogen from steam methane reforming is called “grey” hydrogen, but if the CO2 from the process is collected and injected underground (carbon capture and storage), it is labeled “blue” hydrogen.

Hydrogen is an important component in the drive toward lower carbon emissions. Its future uses may include long-term energy storage to back up intermittent electricity sources, a replacement for metallurgical coke in the steelmaking process, a source for the manufacture of synthetic fuels, and a fuel source for industrial processes that currently use natural gas or coal for heating.

Perhaps the most important use for hydrogen is in the making of ammonia (NH3) which is the base chemical used to make nitrogen fertilizers. The manufacture of ammonia for fertilizers accounts for about 1% of the world’s carbon emissions. It doesn’t sound like much, but it is a very important 1% because the use of fertilizers has enabled us to double world food production. Replacing natural gas as the hydrogen source in ammonia is vital to maintaining our food supply in a zero-carbon economy.

Emissions from the making of hydrogen by electrolysis are dependent entirely on the source of electricity, the process itself produces no carbon emissions. However, it takes about 50 KWh of electricity to make 1 Kg of hydrogen by electrolysis, so to make hydrogen that has lower emissions than that made from steam methane reforming, electrolytic hydrogen must be made with electricity from a power supply that emits less than 186 g/KWh.

The accepted definition of “green” hydrogen specifies that the power source must have carbon emissions below 30 gCO2/Kwh

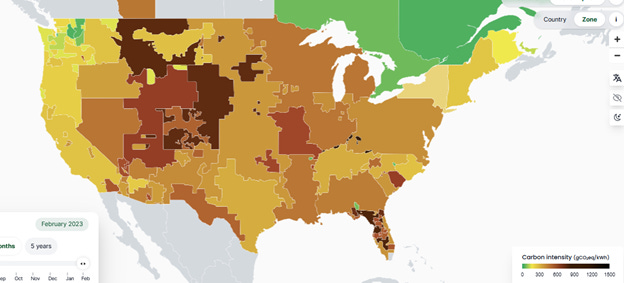

Here’s a map of the USA, showing the carbon intensity of the electrical power consumed in each area (averaged over 12 months). To produce hydrogen with a lower carbon footprint than SMR hydrogen you need to get your power from one of the areas shown in green.

As you can see, there are very few places in the USA where you can use electricity from the grid to make hydrogen that has a lower carbon footprint than the hydrogen made by SMR. In fact, there aren’t any places because those areas that have low grid carbon intensities also export hydroelectric power to other areas, so adding a hydrogen plant using that power would simply be depriving the other areas of “green” power and forcing them to make up the shortfall with fossil fuels.

The situation is worse than I describe because when the electrolytic hydrogen plant is added to the grid, the sun doesn’t shine brighter, the wind doesn’t blow harder, there is no extra rain to provide more hydropower and the nuclear plants are running at full capacity. The energy must come from burning fossil fuels, there is no other source.

There is nowhere in the USA where hydrogen can be made by electrolysis using grid power without increasing CO2 emissions beyond the emissions that would be produced by making that hydrogen using steam methane reforming.

Electricity maps provide emissions data from many of the world’s power grids. The only grids that have emissions below the 30 gCO2/KWh that is the limit for making “green” hydrogen are Quebec, parts of Norway and Sweden, and Iceland.

The table below shows the emissions from making hydrogen using fossil fuels as an electricity source:

As you can see, operating an electrolyzer plant with as much as 30% natural gas-generated electricity will result in emissions higher than those from steam methane reforming, and coal-generated electricity would have to be limited to less than 20%. In fact, making ”green” hydrogen is only possible if almost all the electricity comes from low-carbon sources.

However, what we are seeing in the USA are proposals for hydrogen plants that are clearly intended to operate at full power 24 hours/day, 365 days per year while claiming to make “green” hydrogen. For example, this one proposed by HIF Global for Matagorda, Texas will make hydrogen by electrolysis and use CO2 captured from the air to manufacture methanol and synthetic gasoline. 1.8 Gw of electrolyzers will be used to produce 300,000 tonnes per year of hydrogen.

But to produce that much hydrogen from 1,8 Gw of hydrolyzers the plant will have to operate at full capacity 24 hrs/day and 350 days per year. HIF Global claims that the plant will operate on wind power, but how is that even possible when it must operate continuously at full power to reach its stated capacity?

This one, the Sauk Valley “green” hydrogen project targets 6 Kg/hr and 52 tonnes per year from solar power. But it can only do that if the sun shines 24 hours per day, every day in Illinois.

Or this one, the Avangrid Hydrogen Project in Connecticut, estimated to produce 2,900 tonnes of H2 per year using 20 Mw of electrolyzers powered by wind and “grid renewables”, but only possible if it runs continuously at full power 24 hrs/day.

The dilemma for hydrogen producers is this:

· Hydrogen electrolyzer plants are expensive, to minimize costs they need to be operated at full capacity 24 hours/day

· If they are operated on dedicated wind and solar power, they cannot achieve more than about 50% capacity factor.

· If connected to the grid, where they can operate at full power 24 hrs/day, they don’t produce “green” hydrogen, and in most cases, they will emit more CO2 than a steam methane reforming plant making the same amount of hydrogen.

To help get over this dilemma, there is a requirement for “additionality”. The hydrogen plant must be connected to renewable resources that are added to the grid rather than existing resources. However, that doesn’t make the hydrogen “green”. If the grid is using a mix of renewables and fossil fuels and there are no surplus renewables, then adding the extra load from the hydrogen plant always increases the use of fossil fuels.

To qualify as truly “green”, hydrogen can only be made when there is a surplus of renewables. The EU is phasing in a rule with that requirement (called “hourly matching”), where hydrogen made by electrolysis will only qualify for green subsidies if it is made from surplus renewables.

However, there is nowhere in the USA where surplus renewables can provide power to a hydrolyzer plant for even a 50% capacity factor.

A group of companies in the hydrogen business is lobbying the US government to allow green hydrogen subsidies based on “annual matching”. That is, if renewables are added to the grid and produce 1 GWh of energy in a year, then a hydrogen plant that draws 1 GWh of energy can qualify as green. A copy of a letter from those companies to the US Treasury, The Dep’t of Energy, and The White House can be found in this link.

The proposed “green” hydrogen tax credits are substantial (up to $3/Kg of hydrogen), they make the difference between a viable and a non-viable business case for most projects, and it is unlikely that a significant hydrogen industry will develop without those subsidies because hydrogen made by electrolysis is much more expensive than hydrogen made by steam methane reforming.

However, depending on how the rules are formulated, the US taxpayer could end up subsidizing a lot of hydrogen production that not only fails to reduce CO2 emissions but in some cases significantly increases those emissions. Production of carbon-free hydrogen is a cornerstone of the climate change initiative, but like many things associated with renewable power, the facts don’t always match the perceptions.

As Kermit the Frog said – “It ain’t easy being green”

In my next article, I will show how much extra renewable capacity is needed to make green hydrogen and how difficult it is to make hydrogen by electrolysis using surplus renewables. (I hope to publish it in the next two weeks).